ChocLine Printer

For my Chemical Engineering capstone design project, my teammates and I investigated fluid and thermodynamic properties of chocolate in order to improve upon 3D Printing of chocolate.

Currently, 3D Printing is a relatively novel idea in the food industry. There are 3D printers designed for chocolate in the market, but all of them come with extremely specific temperature and speed parameters for printing chocolate.

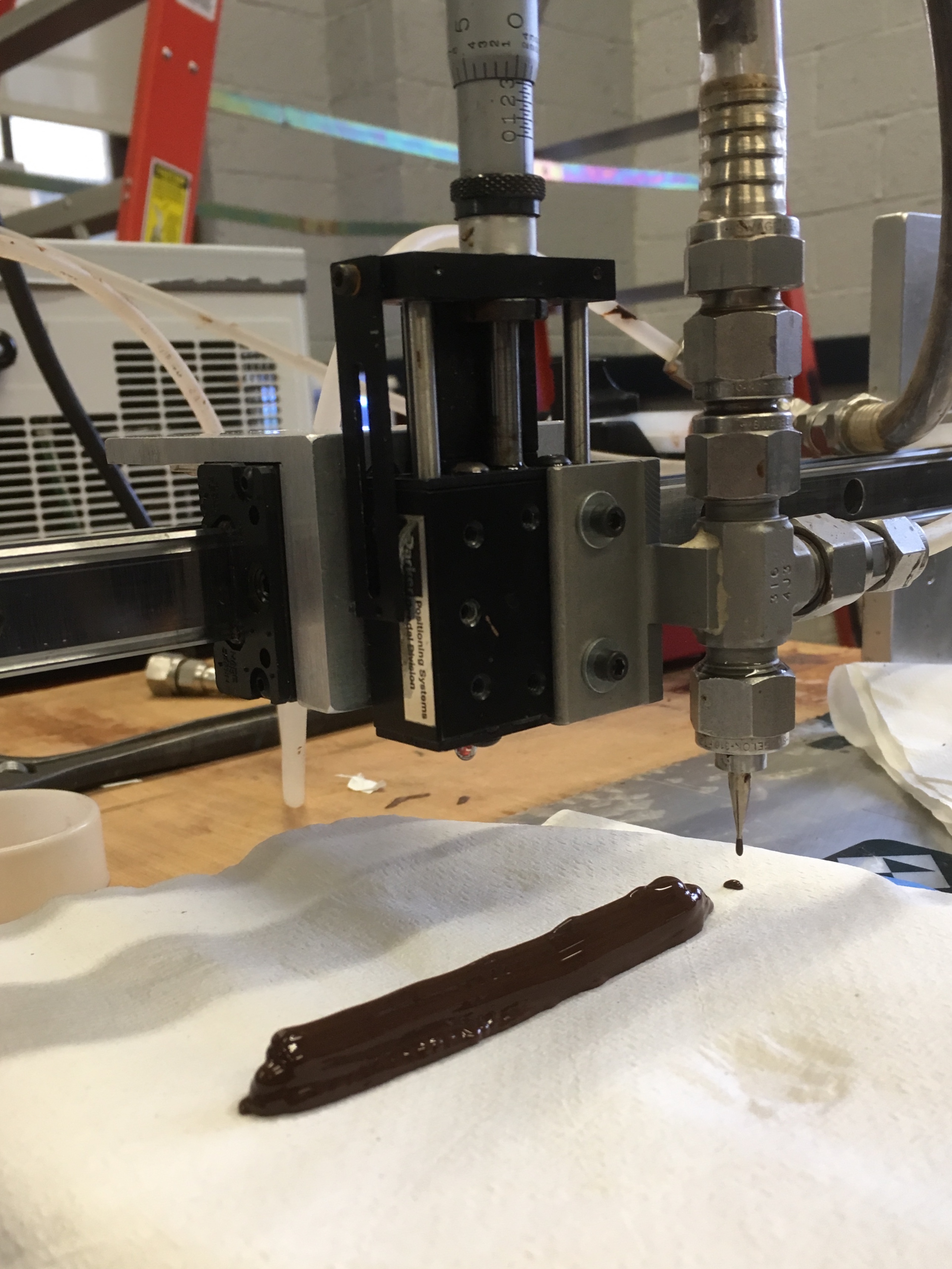

My team and I sought to improve upon the printing process by investigating optimal flow parameters. We designed a simple 3D Printer for chocolate that went back and forth in a straight line. The line of chocolate was kept warm through a double pipe heat exchange where warm water surrounded the melted chocolate.

To keep the chocolate warm enough to print, we used a double pipe heat exchange system where the chocolate was surrounded by warm water to keep it at a consistent temperature. To test out which combination of flow parameters worked best for the printer, we varied the extrusion rate (rate of chocolate coming out of a nozzle) and the linear rate at which the chocolate was moving back and forth.

Ultimately, we wanted to determine the combination of chocolate extrusion rate (rate of chocolate coming out of a nozzle) and the linear rate at which the chocolate was moving back and forth. We concluded that the volumetric flow rate of chocolate coming out of the nozzle head should be as similar as possible to the velocity of the nozzle moving back and forth, but the setup can still work when the extrusion is twice as fast as the linear speed.